Chapter 6 of Class 12 Chemistry, titled “General Principles and Processes of Isolation of Elements,” focuses on the various methods used to extract and refine metals from their natural sources, known as ores. The chapter begins by explaining the concept of metallurgy, which involves the extraction of metals from ores and their subsequent refinement.

The first step in metallurgy is the concentration of ores, where impurities like sand and clay are removed to increase the metal content. Various methods such as hydraulic washing, magnetic separation, and froth flotation are discussed.

Next, the chapter covers the conversion of concentrated ores into their oxides through processes like roasting and calcination. Roasting involves heating the ore in the presence of oxygen, while calcination involves heating in the absence or limited supply of air.

The reduction of metal oxides to obtain the pure metal is another crucial topic. This can be done using various reducing agents such as carbon, carbon monoxide, or even more reactive metals. The chapter also introduces the thermite reaction, a highly exothermic reaction used for welding metals.

Electrolytic reduction and refining processes are explained, where metals are purified through electrolysis. This method is particularly important for metals like aluminium and copper. The chapter also touches upon the refining of metals using methods like distillation, liquation, and zone refining.

The chapter concludes with the study of some specific metallurgical processes like the Bayer process for aluminium, the Hall-Héroult process for the extraction of aluminium, and the Mond process for refining nickel. The role of Ellingham diagrams in predicting the feasibility of reduction reactions is also highlighted.

Class 12 Chemistry Chapter 6 General Principles and Processes of Isolation of Elements. Book 📚📚 Download

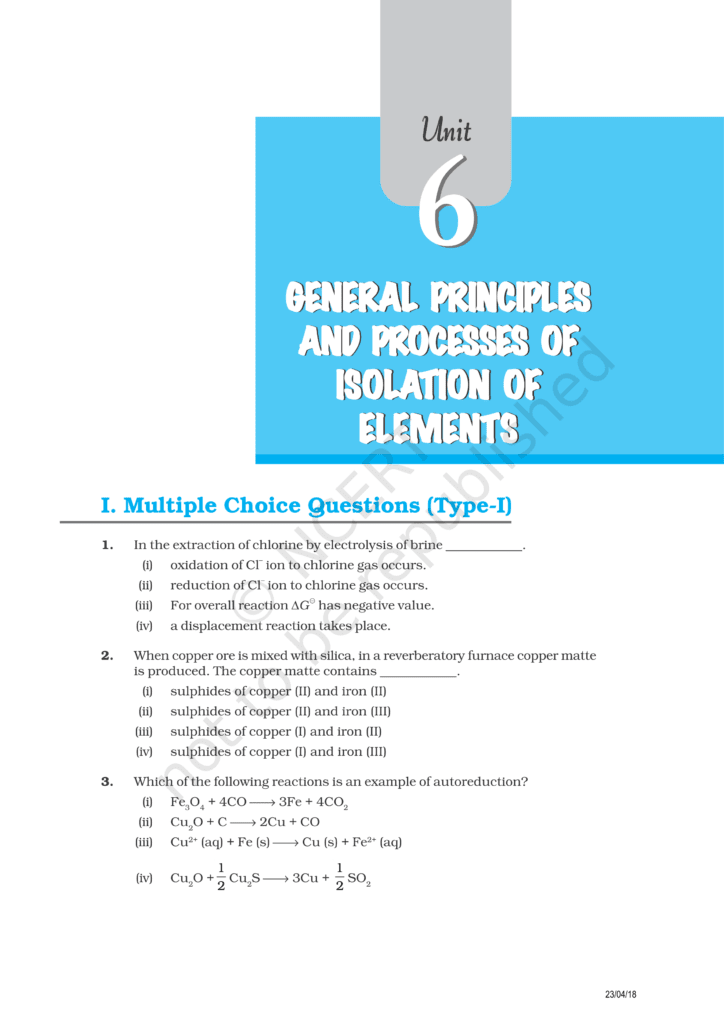

Question & answer

1. What is metallurgy?

Metallurgy is the process of extracting metals from their ores and refining them for use. It involves various steps, including ore concentration, reduction, and purification.

2. Explain the term ‘concentration of ore’.

Concentration of ore refers to the process of removing impurities like sand, clay, etc., from the ore to increase the metal content. This can be done by physical or chemical methods.

3. What is froth flotation process?

The froth flotation process is used for the concentration of sulphide ores. In this process, the ore is mixed with water and pine oil, and air is passed through the mixture, creating froth. The ore particles cling to the froth, which is skimmed off, leaving behind the impurities.

4. Define roasting.

Roasting is a metallurgical process involving the heating of ore in the presence of excess air or oxygen. It is mainly used for sulphide ores to convert them into oxides.

5. What is calcination?

Calcination is the process of heating the ore strongly in the absence or limited supply of air. This process helps in the removal of volatile impurities and moisture, converting the ore into a more workable form.

6. Explain the role of limestone in the extraction of iron.

Limestone is added to the blast furnace in the extraction of iron from its ore. It acts as a flux, combining with the impurities to form slag, which is removed from the furnace.

7. What is the thermite reaction?

The thermite reaction is a highly exothermic reaction between aluminium powder and a metal oxide, usually iron oxide, producing aluminium oxide and molten iron. It is used for welding and cutting metals.

8. Explain the process of leaching in metallurgy.

Leaching is the process of extracting a metal from its ore by using a chemical solvent. For example, gold is leached using cyanide solutions, where the metal dissolves and is later precipitated.

9. What are the different methods of refining metals?

Some common methods of refining metals include distillation, liquation, electrolytic refining, zone refining, and vapour-phase refining. Each method is chosen based on the metal’s properties and impurities.

10. What is electrolytic refining?

Electrolytic refining is the process of purifying impure metals by using electrolysis. The impure metal is made the anode, and the pure metal is deposited at the cathode.

11. Describe the principle behind zone refining.

Zone refining is based on the principle that impurities are more soluble in the molten state than in the solid state. A rod of impure metal is passed through a heater, and as it melts and solidifies, the impurities concentrate in the liquid phase and move along the rod, leaving behind purified metal.

12. What is Mond’s process?

Mond’s process is a method for refining nickel. In this process, impure nickel reacts with carbon monoxide at high temperatures to form nickel carbonyl, which decomposes to yield pure nickel.

13. Explain the significance of Ellingham diagrams.

Ellingham diagrams are graphical representations that show the temperature dependence of the stability of compounds. They are used to predict the feasibility of reduction reactions in metallurgy.

14. What is the role of coke in a blast furnace?

Coke serves as both a reducing agent and a source of energy in the blast furnace during the extraction of iron. It reduces the iron oxide to iron and generates the high temperatures required for the process.

15. Describe the Bayer process.

The Bayer process is used for the extraction of alumina (Al2O3) from bauxite ore. The ore is first treated with sodium hydroxide, which dissolves the alumina, and the impurities are removed. The alumina is then precipitated from the solution.

16. What is the purpose of flux in metallurgical processes?

Flux is a substance added during the smelting of ores to remove impurities in the form of slag. It helps in lowering the melting point of the impurities and facilitates their removal.

17. Explain the concept of hydrometallurgy.

Hydrometallurgy involves the extraction of metals from their ores using aqueous chemistry. This includes leaching, solution concentration, and metal recovery. It is widely used for metals like gold, silver, and copper.

18. What is the Hall-Héroult process?

The Hall-Héroult process is an electrolytic method used to extract aluminium from alumina. In this process, alumina is dissolved in molten cryolite and electrolyzed to produce pure aluminium.

19. Describe the Van Arkel process.

The Van Arkel process is used to obtain ultrapure titanium and zirconium. The impure metal is converted into a volatile compound, which is then decomposed on a hot filament to yield pure metal.

20. What is the role of slag in metallurgy?

Slag is a byproduct formed during the smelting of metals. It consists of impurities and flux. The slag floats on the molten metal and can be easily removed, ensuring that the metal obtained is pure.

Get involved!

Comments